Axles and Shaft-Certified Balancing

At Lambert Engineering, our Axles and Shaft-Certified Balancing service ensures smooth, efficient operation. Experienced technicians employ precision methods to align, rotate, and harmonize shafts. Through specialized testing and certification, we guarantee consistent performance, minimized vibration, and enhanced safety for optimal function in diverse industrial applications, prolonging your equipment’s overall life.

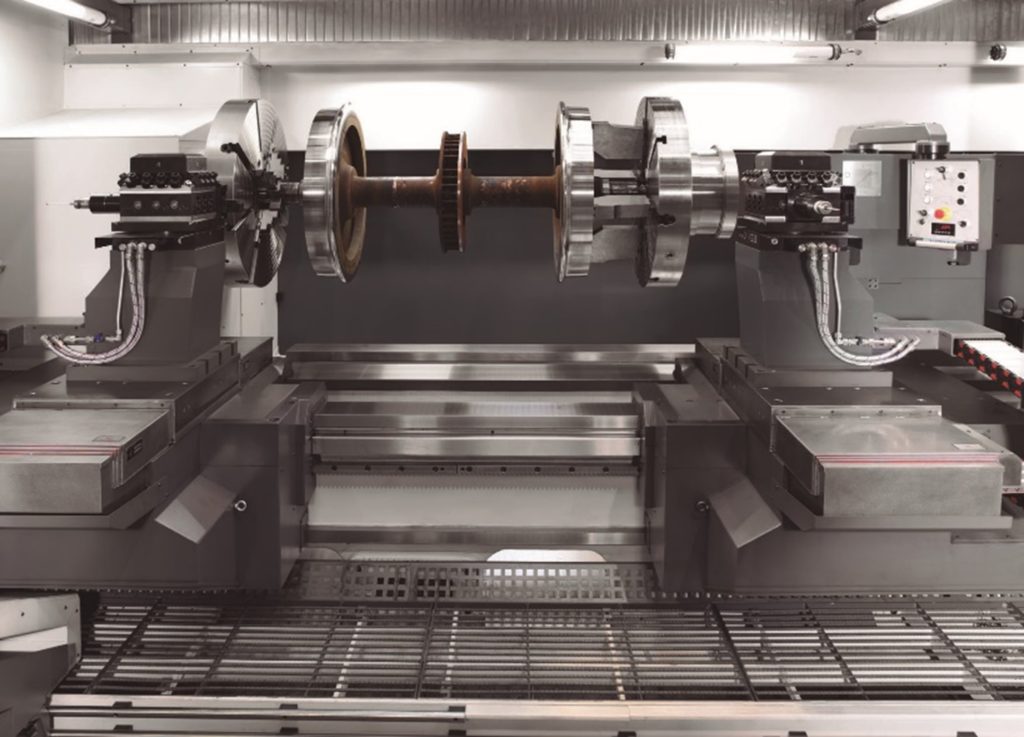

Our certified balancing machines provide you with the desired end product.

We are able to provide you with a certification on your balance equipment..

Axles & Shaft Certified Balancing

A typical axle and shaft-certified balancing process involves several key steps:

- Initial Inspection

The axle or shaft is thoroughly examined for signs of wear, damage, or misalignment. Any visible issues are documented for potential repair or replacement. - Measurement and Runout Check

Technicians measure shaft straightness (runout) and critical dimensions. Specialized gauges and instruments ensure accurate assessment of deviations from design specifications. - Repair or Replacement of Damaged Components

If bent or broken elements are identified, they’re either repaired (such as straightening a bent shaft) or replaced entirely with new, precision-manufactured components. - Pre-Balance Setup

The shaft or axle is mounted on a specialized balancing machine. Proper alignment and secure clamping help guarantee accurate test results. - Balancing

Using advanced balancing equipment, technicians rotate the shaft at operational speeds, measuring imbalance forces. Weights may be added or material removed at precise locations to achieve the correct balance. - Verification and Certification

After each adjustment, the shaft is retested until the measured vibration is within acceptable tolerances. Once optimal balance is achieved, the shaft’s balance specifications are documented, and a certification is issued. - Final Inspection and Installation

A final inspection confirms the component meets industry standards. Proper labeling and documentation conclude the process before reinstallation, ensuring smooth, efficient, and safe operation in its intended application.