Hydraulic Cylinder Rebuilds

Lambert Engineering’s Hydraulic Cylinder Rebuilds restore critical components to peak condition. Our expert technicians dismantle, inspect, and replace worn parts before reassembling and testing every cylinder. This precision approach reduces downtime, improves equipment reliability, and extends service life. Count on our proven expertise to keep your hydraulic systems operating seamlessly.

Hydraulic Cylinder

The turn around on a rebuild of a Hydraulic Cylinder can be as short as five days.

Hydraulic Cylinder Rebuilds

A hydraulic cylinder rebuild typically follows these key steps:

- Initial Inspection and Disassembly

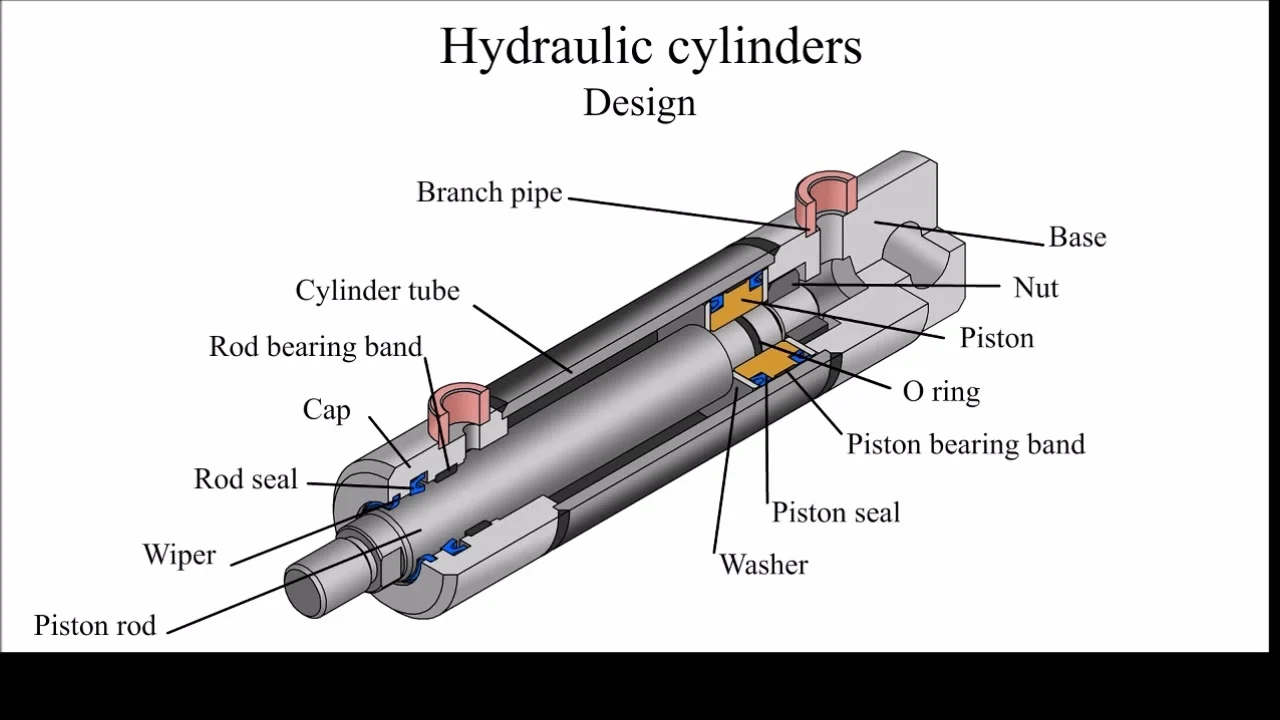

The cylinder is carefully removed from the machine, disassembled, and all components—rod, piston, seals, and bearings—are visually examined for signs of wear, corrosion, or damage. - Cleaning

Parts are thoroughly cleaned to remove dirt, grime, and fluid residue. This step ensures accurate inspection and proper fit during reassembly. - Detailed Evaluation

Critical measurements are taken of the cylinder bore, piston, and rod. Technicians look for pitting, scoring, bending, or other imperfections that could compromise performance. - Refinishing or Machining

If damage is found, parts are either resurfaced or machined. In cases of severe wear, replacements may be necessary. This ensures proper tolerances and extends cylinder life. - Seal and Component Replacement

Worn seals, O-rings, gaskets, and any other parts showing degradation are replaced with high-quality, OEM or equivalent components to prevent leaks and restore functionality. - Reassembly

The cylinder is reassembled methodically using correct torque settings, lubricants, and best-practice assembly techniques, ensuring all new and refurbished parts fit correctly. - Testing and Final Inspection

The rebuilt cylinder is tested under pressure to confirm it holds hydraulic fluid without leaks and operates smoothly. A final inspection verifies compliance with industry standards before returning the cylinder to service.